Leveraging RFID Label Tech, Part One: RFID Basics

Due mostly to new label requirements with big box retailers, Radio-frequency identification (RFID) technology is a hot topic in the labeling industry. Anyone along the label supply chain, from retailers to distributors, is now in a position where increased knowledge about RFID is fast becoming a requirement.

Due mostly to new label requirements with big box retailers, Radio-frequency identification (RFID) technology is a hot topic in the labeling industry. Anyone along the label supply chain, from retailers to distributors, is now in a position where increased knowledge about RFID is fast becoming a requirement.

In this 3-part series, Leveraging RFID Tech, we’ll introduce this technology, what it means for label distributors, and what it could mean for the future of the label industry. This first article offers some initial details, a little history, and its foreseeable impacts on our industry.

RFID harnesses electromagnetic fields to automatically identify and track tags affixed to objects. These tags contain electronically stored data, easily readable from afar using a special RFID reader.

RFID tags can either be passive or active. Active RFID tags are powered by the RFID reader’s electromagnetic fields. Passive RFID tags have their own power source which boosts their signal transmission.

An RFID system, with good backend software for data storage and management, seems to outperform traditional barcode systems. Real-time tracking and enhanced inventory accuracy and authentication create more efficiency across the board.

Yet, as we speak, RFID is also evolving. For example, new temperature monitoring sensors and tamper detection capabilities have emerged, accelerating the continued adoption of RFID in retail, healthcare, logistics, manufacturing, and many other industries.

Origin of RFID

Born out of necessity in WW2, the British invented a precursor to RFID that was used to identify if a ship was a “friend” or “foe.” After various experiments and developments with RFID tag technology in the 1950s and 60s, the modern version surfaced in the 1970s, patented by Charles Walton.

The technology remained largely unchanged until the 1990s, when the world saw remarkable strides in microelectronics, wireless communication, and the internet, catapulting RFID into commercial applications such as livestock tracking and access control. The most widespread public adoption of RFID occurred with the infamous “EZ-Pass” at toll checkpoints, revolutionizing vehicle tracking and revenue collection.

Over time, RFID’s applications expanded across retail, supply chain

management, and healthcare. With continual evolutions in efficiency, security, and real-time tracking capabilities, RFID will eventually permeate most relevant commercial sectors.

RFID Technology in Labels

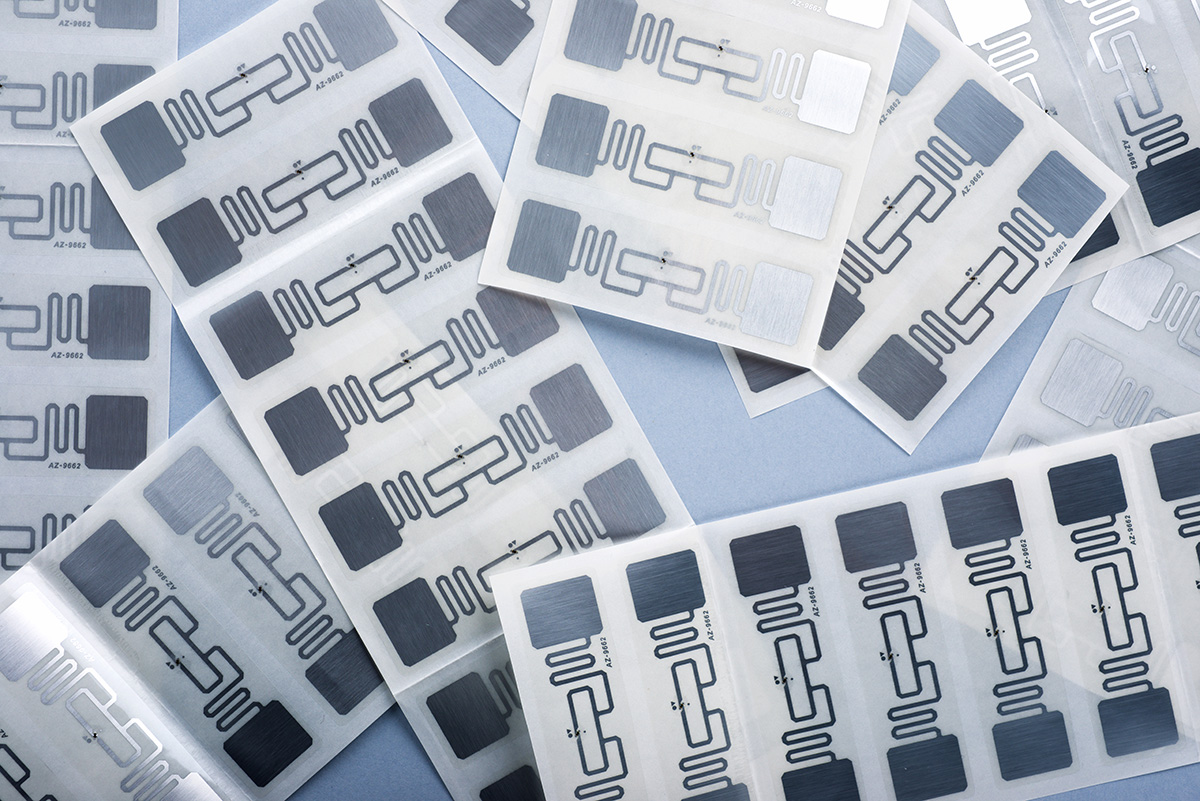

RFID labels efficiently store copious information in a compact format, facilitating streamlined data management and tracking across the supply chain.

Unlike conventional barcode labels, RFID labels obviate the need for line-of-sight scanning, ensuring swift and accurate identification even amid stacked or obscured items. This attribute significantly elevates inventory management and mitigates errors.

Additionally, RFID labels endure harsh environmental conditions and seamlessly integrate into existing packaging or products, catering to diverse industries including manufacturing, retail, and logistics.

Moreover, RFID technology enables real-time tracking and monitoring of labeled items, furnishing invaluable insights into their whereabouts, condition, and transit. This capability amplifies supply chain visibility, enables proactive decision-making, and mitigates the risk of asset loss or pilferage.

Resembling conventional pressure-sensitive labels, RFID labels feature a UHF RFID transponder located between the facestock and release liner. These transponders, or inlays, employ microchips and antennas to store and transmit data to RFID readers. Specialized printer encoders facilitate data encoding on the inlay, enabling additional data printing such as traditional barcodes or shipping information.

Harnessing RFID Labels for Business Growth

Label distributors can easily craft a compelling story about the features and benefits of RFID labels for their clients.

For example, no matter the industry, RFID labels seem to fortify operations and spur growth. By optimizing inventory management, RFID technology streamlines supply chain processes, curtails stockouts, and minimizes excess inventory, thereby translating into cost savings and augmented profitability. As industries prosper, other industries notice and hop on the bus.

Distributors could note that the real-time tracking prowess of RFID labels empowers companies with enhanced visibility into their assets and shipments, facilitating informed decision-making and nimble responses to market dynamics. Such agility bestows any company with a competitive edge and certainly empowers them to capitalize on market opportunities.

RFID labels contribute to an enriched customer experience by ensuring product availability, truncating checkout times, and enabling innovative services such as personalized recommendations grounded in purchase history. Gratified customers become loyal patrons and then, perhaps, fierce brand advocates.

Let’s zoom out a bit. By automating manual tasks and reducing errors, RFID labels liberate resources that can be redirected toward strategic initiatives and business development endeavors. This heightened efficiency propels company growth by fostering scalability and expediting time-to-market for new products and services.

Successful distributors find ways to unlock fresh avenues of growth for their clients. By helping clients understand how they can capitalize on the benefits of RFID technology, distributors can also ride this “new” technology wave.